What is Polyaspartic Flooring?

Polyaspartic flooring has been available since the 1980s, and its primary application is on piers or bridges.

Polyaspartic flooring has been available since the 1980s, and its primary application is on piers or bridges. More recently, it has become a popular garage floor covering thanks to its visual appeal and durability.

This article provides all the information homeowners require to decide whether polyaspartic flooring suits their workshops and garages.

The composition of polyaspartic floors

A combination of isocyanate and resin, polyaspartic flooring protects metal and concrete surfaces. Professionals apply it by spraying it onto the chosen surface with relatively short drying times.

Apart from providing outstanding durability and toughness, polyaspartic flooring doesn’t require much maintenance and adds industrial-style appeal.

Polyaspartic flooring combines an isocyanate base and an aliphatic polyaspartic top coat. The polyurea base coat bonds the surface, while the polyaspartic top coat creates a glossy abrasion- and chemical-resistant finish. Car showrooms and manufacturing facilities often have polyaspartic flooring.

While polyaspartic floor coatings are more expensive than traditional garage floor coatings, they have many advantages, including added durability and heat and UV resistance.

Polyaspartic vs. polyurea garage flooring

Beyond the price difference, polyaspartic and polyurea floorings have different curing properties, with the latter drying more slowly. Typically, polyaspartic flooring is ready for heavy traffic within 24 hours, while the curing period for polyurea flooring is 72 hours.

Polyaspartic flooring pros and cons

While around 20% more expensive, polyaspartic garage floor coating is more hard-wearing and stands up well to heat and chemicals. The application takes skill, and this flooring is only suitable for specific surfaces.

Pros

Quick and easy application and fast drying: Professionals layer polyaspartic flooring using a spray, brush, or roller. The flooring contains a low VOC solvent which hastens curing times between coats and shortens the installation time.

Hard-wearing and durable: The compound is resistant to scratching, heat, UV, and chemicals. It bonds well with the chosen substrate.

Abrasion and chemical resistance: The high-cross polymer, aliphatic amine-terminated polyurea, is the main component in polyaspartic flooring and makes it resistant to chemicals and abrasions. The high-gloss finish prevents water damage, while the flooring’s UV resistance maintains the colors.

More eco-friendly: Polyaspartic flooring contains fewer hazardous ingredients. Moreover, the durability and speed of application cut down on overall energy consumption.

Milder fumes: Polyaspartic flooring contains fewer VOCs, resulting in a less pungent odor.

Cons

Higher cost, trickier application: Polyaspartic flooring is not only more expensive to buy, but the application is more complex, resulting in additional expense. Nonetheless, the low maintenance costs over time will offset the initial higher cost.

Prone to acid corrosion: The chemical makeup of polyaspartic flooring makes it vulnerable to acid corrosion. Acidic compounds quickly break down the lightly bonded amino acid molecules in the flooring, leading to corrosion, staining, and weakening.

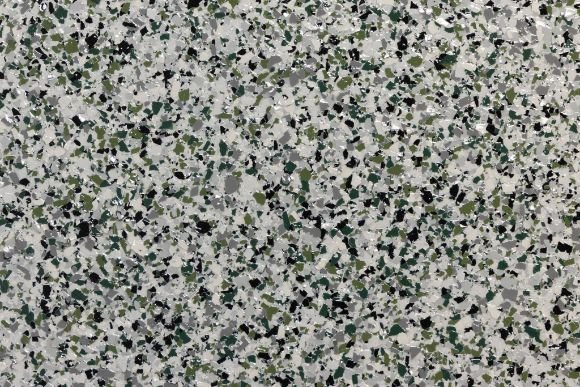

Fewer color options: Compared to other flooring types, polyaspartic flooring is only available in medium to light shades of gray.

High moisture content stops application: Excess humidity prevents bonding, meaning the flooring doesn’t stick properly, bubbles form, and the flooring lifts from the surface.

Glossy means slippery: The polished finish of polyaspartic flooring can make the surface slippery with water exposure. Adding a non-slip additive can counter this drawback, as will creating ridges when applying it with a roller.

The many upsides of polyaspartic flooring

It isn’t surprising that polyaspartic flooring is all the rage now. Please consult a professional for advice on how best to utilize it.

Quick Response Garage Floor Coating offers epoxy, flake, solid, stain, and specialty flooring options to Phoenix Valley residential and commercial clients. Call us today for a free estimate at (602) 428-8626.